From 2012 to 2017, SPRING consolidated gains from consecutive successful USAID projects and made fortification the primary platform for delivering micronutrients to the population of Uganda. Fortification of food with specific micronutrients and vitamins can resolve nutritional deficiencies in women and children that negatively affect growth, survival, and development. SPRING strengthened the capacity of Uganda’s food fortification program, by coordinating national fortification activities, supporting regulation and enforcement, and facilitating demand creation for fortified foods, all of which increase access to fortified foods.

One of SPRING/Uganda’s key achievements has been the revitalization of the National Working Group on Food Fortification (NWGFF), a unique public-private partnership that coordinates the implementation and supervision of all food fortification activities. With SPRING’s support, the working group developed a national strategy, which describes the steps and costs associated with integrating fortification activities into sectoral workplans and budgets over the next five years. After SPRING’s closure, the NWGFF will lead the scale-up of fortification activities to additional food vehicles, facilitate the removal of barriers to fortification, and create incentives for industries to participate.

SPRING has also strengthened regulation and enforcement of fortified foods: monitoring programs, training industry representatives, and enforcing regulations ensure that fortified foods meet acceptable standards and do not exceed safe levels of consumption. Over the last five years, SPRING helped train staff and organisations to test fortified foods, report results, and use data to enforce quality control in food fortification and monitoring and evaluation in Uganda. SPRING also carried out research activities in Uganda that have global implications for fortification programs, namely the validation of iCheck testing methods for analysis of micronutrients in fortified foods, and the validation of testing methods for iodine in salt.

We encouraged the inclusion of small-scale maize millers into the national fortification program by providing them with technical support and by helping create demand for their fortified products. These millers produce less than 20 metric tons of flour per day, and they currently fortify their product on a voluntary basis. We identified best practices and fortification technology options for small-scale millers and organized a national learning and dissemination workshop for millers and suppliers. We assessed the acceptability and feasibility of procuring fortified foods in secondary schools, and linked schools that were interested in procuring fortified flour with local millers. SPRING produced an advocacy video featuring the findings as a way to increase national demand for fortified products.

Fortification costs are an important consideration in the design and implementation of a new program, and added costs can be passed along to the consumer. To increase awareness of the benefits of fortified staple foods, SPRING supported the development of Uganda’s Nutrition Advocacy and Communication Strategy (NA&C), which promoted the use of the fortification logo—the big blue “F”—in communication messages. We created radio spots, posters, and danglers, which were displayed at the point of purchase. We also developed a cartoon video featuring a well-known character, Katoto, who promotes the use of fortified products in the preparation of local street foods and demonstrates how to recognize fortified foods.

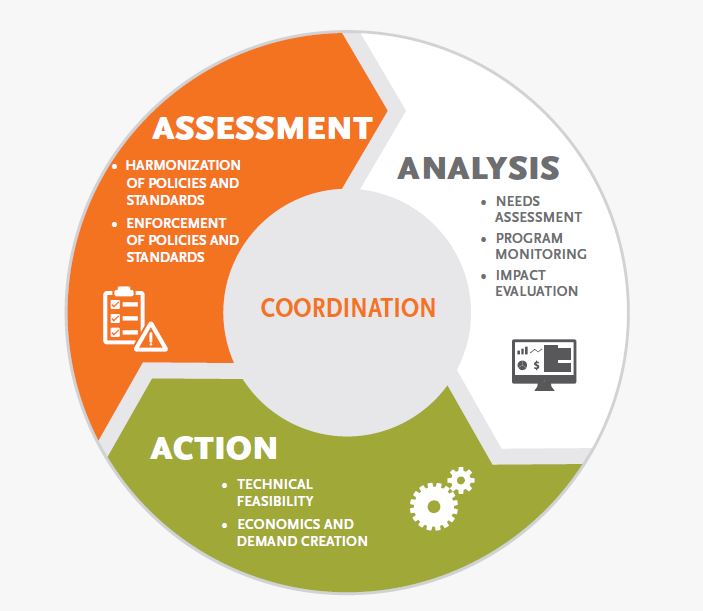

This report illustrates SPRING’s contributions to Uganda’s national food fortification program, using SPRING’s adapted framework to assess food fortification programs, which is based on UNICEF’s Triple A approach.

Introduction

Adding micronutrients and minerals to edible foods, also referred to as food fortification, is a cost-effective intervention to enhance micronutrient intake as a means of increasing national productivity and prosperity. Micronutrient deficiencies often have no visible side effects until the deficiency is severe but can affect an individuals’ health, productivity, and cognitive function. Food fortification along with dietary diversification, breastfeeding, distribution of vitamin and mineral supplements to vulnerable groups, and nutrition-sensitive agriculture, are key aspects of a cohesive strategy to reduce micronutrient deficiencies.

In the president’s National Development Plan, Uganda Vision 2040, the government of Uganda identified reducing micronutrient deficiencies as a priority and adopted fortified staple foods as an approach in the Uganda Nutrition Action Plan (UNAP) of 2011–2016.

From 2012 to 2017, the USAID-funded SPRING project consolidated gains from consecutive successful USAID projects and made fortification the primary platform for delivering micronutrients to the population of Uganda. SPRING built the capacity of Uganda’s food fortification program by coordinating national fortification activities, supporting regulation and enforcement, and facilitating demand creation.

SPRING adapted UNICEF’s Triple A approach as a framework to assess food fortification programs (UNICEF 1997). This sequence of coordination, assessment, analysis, and action is an iterative framework to evaluate and implement food fortification programs. Each section of this report corresponds to the steps on our food fortification framework (Figure 1).

Figure 1. SPRING’s framework for the food fortification program (adapted from UNICEF’s Triple A approach). This framework serves as an outline for this report on SPRING's contribution to industrial food fortification in Uganda.

Coordination

Food fortification programs incorporate public and private sector activities, with the private sector fortifying the products and the public sector guaranteeing the quality and coverage of the fortified foods. As a result, a cross-sectoral group is required to oversee fortification activities. In Uganda, the NWGFF provides leadership in coordinating and supervising the national food fortification program. SPRING became a major stakeholder in large-scale industrial food fortification through its support for the NWGFF, which the Ministry of Health (MOH) tasked us to revitalize in 2012. The NWGFF is a unique public-private partnership, composed of government sector ministries, United Nations (UN) agencies, food and grain associations, food processing industries, the private sector, academic and research institutions, civil society, parastatal institutions, government agencies responsible for regulatory monitoring, and development partners.

SPRING supported quarterly meetings of the NWGFF and technical subcommittees which provided a forum for updates on food fortification across sectors, presenting policy documents for approval and sharing resources. SPRING also organized industry visits for National Anemia Working Group (NAWG) members to identify challenges to and facilitators of industry-level fortification. This regular ongoing coordination facilitated sectors’ integration of fortification into their activities.

With SPRING’s assistance, the NWGFF Secretariat developed a five-year, multi-sectoral food fortification strategy, with a draft budget, action plan, and a monitoring and evaluation framework. The National Industrial Food Fortification Strategy outlines processes to increase production, trade, and consumption of fortified foods in Uganda and emphasizes that private- and public-sector cooperation is integral to the sustainability of the programme. It also addresses the need for a policy framework to guide the implementation of fortification regulations and provides guidance for industrial fortification of major food vehicles produced and consumed in large quantities, which may fall under mandatory or voluntary fortification policies.

To ensure sustainability of the working group, the MOH must find a way to convene the NWGFF without outside support. Currently, a SPRING staff member helps the secretariat by planning the quarterly meetings. SPRING staff’s responsibilities include compiling materials and presentations for the working group, planning logistical support, and mobilising participants to attend. SPRING staff also compiled activity reports for each NWGFF meeting. In its final project year, SPRING will transition these duties and all SPRING-supported fortification activities to the NWGFF. Although another external agency or implementing partner may be able to provide support, the MOH secretariat should consider other options to coordinate the NWGFF.

The national food fortification strategy and associated costing report provide the estimated resources needed to integrate fortification activities into sector budgets and work plans. The idea is for government sectors to use the strategy to prioritize food fortification activities for integration into their annual work plans and budgets. The NWGFF will lead this process and be instrumental in coordinating and mobilising resources from sector government ministries and development partners. Sectoral planning and coordination is expected to be a biannual process. The strategy’s costing report specifies that sectors, agencies and local government will need to identify 250 focal people for fortification programmes.

Needs Assessment

To understand the status of prior and ongoing fortification activities, SPRING and the MOH conducted an assessment of the public sector in 2015. This assessment guided subsequent planning and implementation of SPRING activities, and informed the draft National Industrial Food Fortification Strategy.

We identified several factors to be addressed for efficient implementation of fortification activities including regulatory system challenges and inadequacies, poor surveillance and monitoring systems, poor compliance to standards and regulations, and lack of coordination by participating program sectors. We also identified policy-related challenges, namely the exclusion of food fortification activities from sector work plans and budgets, and low demand for fortified foods.

Over the subsequent two years, SPRING targeted programs around the areas identified in the public sector readiness assessment. To monitor progress, SPRING and the government developed a centralized system to track fortification information across sectors. This monitoring and evaluation framework includes indicators on internal and external compliance with fortification standards, as well as household indicators (i.e. use and coverage of fortified foods). The framework also includes key results, indicators, methods, and frequency of data collection for regulatory monitoring and the impact evaluation.

Technical Feasibility

Maize flour is an ideal vehicle for food fortification in Uganda because it is widely consumed, can easily be altered to include additional micronutrients, and can be fortified without a change in taste, smell or appearance. However, the majority of Ugandans consume unfortified maize flour produced by small-scale maize millers, or millers who produce less than 20 metric tons per day and thus are not mandated to fortify. Although small and medium enterprises (SME) have been trained on certain aspects of fortification, they need additional support with appropriate technology and logistics. At the national and regional levels, SPRING has supported smallscale millers to voluntarily fortify by identifying best practices and technology options for small- and medium-scale millers, providing training on record keeping, good manufacturing practices, good handling practices, and food fortification stands, and by building demand to encourage fortification.

SPRING supported the Ministry of Trade Industries and Cooperatives (MTIC) to train small- and medium-scale maize millers on food fortification and good manufacturing and hygiene practices. The training encouraged millers to improve their manufacturing practices and to use food fortification as one way to promote added value to maize flour. Maize millers were advised to form a maize millers association to strengthen their influence and increase their bargaining power.

SPRING, in partnership with Feed the Future’s Commodity Production and Marketing Activity, supported the organization of medium and large-scale maize millers into one association, where the maize millers nominate and elect the leaders. The association serves as a platform where millers can share lessons, challenges, and recommendations on maize flour processing and fortification.

For small-scale millers, in particular, SPRING in partnership with MTIC and the Private Sector Foundation Uganda (PSFU) supported the mobilization of maize millers into clusters. The cluster groups were formed based on the existing associations of small and medium-scale millers from the different regions. The clusters include the Nateete- Rubaga Grain Millers Association and the Kisenyi Grain Millers Association in the central region.

In 2016, SPRING conducted a survey of small and medium scale millers and found that the majority of millers face challenges with poor quality or reliability of electricity, non-food grade milling equipment, and low access to start-up and working capital. Small-scale maize millers cannot afford to buy or maintain standard fortification equipment and need support from outside partners.

In line with SPRING’s efforts to learn best practices from the East, Central and Southern African Health Community (ECSA-HC) member states, SPRING sponsored members of the NWGFF’s exchange learning visit to the Sanku Project in Tanzania, which implements maize flour processing and fortification using appropriate technology for small- and medium-scale millers. The visit was an opportunity to draw lessons to strengthen Uganda’s food fortification program.

SPRING assessed and documented fortification technology options available for small-scale millers in the region and their relevance in the Uganda context. After conducting focus group discussions with small and medium-scale millers, we documented the challenges that millers face in adopting fortification technologies, the support millers currently receive, and frequently asked questions on fortification. We presented these findings at a learning and dissemination workshop with Feed the Future and CPM. We also prepared a technical brief for future implementing partners to consult when seeking to support fortification technology for small-scale millers.

The PSFU has offered to continue to support food fortification for organized business groups, by providing grants (currently USD $18 million) for industrial infrastructure, technology development, and capacity building in the area of fortification. PSFU can also help small- and medium-scale millers engage in government advocacy to address their concerns. The NWGFF should follow up on the MTIC’s and the PSFU’s opportunities and incentives offered to SME. The working group should also support the formation of SME associations, by providing logistical and planning support.

Economics and Demand Creation

Fortification costs are an important consideration in the design and implementation of a new program. Industries have to invest in fortification equipment, including feeders to combine the minerals/vitamins with the food product, as well as in quality control processes and in procuring the minerals and vitamins premix. The government has added cost hiring inspectors and enforcers of fortification quality standards. These added costs can be passed along to the consumer and may result in lower demand for fortified products.

In early 2016, as a way to complement our efforts supporting improvements in fortification technology and standards, SPRING began a campaign to raise awareness of the benefits of fortified staple foods (wheat flour, cooking oil, and maize flour) and promote their consumption. Uganda had a long-established fortified food brand/logo: a big blue “F.” However, the logo was not well known among consumers. To raise public awareness of the benefits of fortified foods, SPRING/Uganda supported the MOH’s Health, Education, and Communication Division to develop communication materials highlighting the benefits of the vitamins and minerals in fortified foods, and noting that these fortified foods can be recognized by the big blue “F” logo found on their packaging. The campaign focused on promoting branded foods as quality products with good value. We made a short social media spot on the popular rolex chappati (flatbread) made with fortified flour, featuring a well-known cartoon character, Katoto. This social media campaign conducted in 2017 enhanced the awareness of the big blue “F”.

To sustain the big blue F brand recognition among consumers, industries need to advertise their brands by promoting the quality of their fortified products. Currently, most private companies that produce fortified products don’t advertise and market the benefits of these foods. They fortify their products because it is legally mandated, but they are not capitalizing on the fact that these fortified foods are an improved product that can be marketed as such. SPRING’s development of the Katoto cartoon ad aims to inspire private companies to follow this lead and play up their fortified products as better quality, drawing attention to the blue “F” logo, which they earned the right to display on their certified products by meeting the regulatory standards we supported the government to enforce.

SPRING, USAID/FANTA and UNICEF jointly participated in supporting the development of Uganda’s Nutrition Advocacy and Communication (NA&C) Strategy which aimed to increase awareness of improved nutrition for women and children during the first 1,000 days. The strategy included a communication plan to support the pro-nutrition activities and household practices outlined in the Uganda Nutrition Action Plan (UNAP) 2011-2016. To support roll out of the NA&C strategy, SPRING and the Office of the Prime Minister (OPM) developed communication messages aimed to raise public awareness of the benefits of consuming fortified food. SPRING supported MOH officials to conduct five radio talk shows on food fortification.

SPRING, in partnership with USAID/Communication for Health Communities (CHC), conducted a mass distribution of food fortification outdoor awareness materials (10,000 posters, 40,000 cutouts) in five regions of Uganda and in five languages, including Luganda, Luo, Rutooro, Runyankole, and Lugbara. The teams worked with community members, including health personnel, to distribute food fortification outdoor materials at high traffic sites including markets, retail shops, health facilities, street walls, community centers, schools, and other meeting points.

In 2017 SPRING produced a short documentary-style video for use by school administrators and head teachers across Uganda to encourage them to purchase fortified foods, particularly maize flour, for their school meals. The daily diet of boarding school students includes posho and beans, where posho is made from locally milled maize flour that is not fortified. The local millers reported that they didn’t fortify their maize flour because there was no demand. SPRING linked smallscale millers and schools interested in fortified products to create that demand and launch real interest in maize flour fortification. The video focuses on what empowering school leaders can do to seek and purchase fortified maize flour for their school.

There are currently no policies in place requiring that large institutions (such as hospitals, schools, and prisons) supply their clients with fortified products. SPRING initiated advocacy meetings with millers and consumers on the benefits of consuming fortified foods, inviting head teachers, school administrators, and millers to participate in group discussion on the procurement of fortified flour. We addressed stakeholders’ concerns relating to the production, procurement, and consumption of fortified flour in schools. These efforts will need to continue and be expanded to other consumer groups and industry owners.

Harmonization of Policies and Standards

SPRING supported the Uganda National Bureau of Standards (UNBS) in training district health inspectors to enforce the East Africa Standards and in efforts to harmonize standards across the region. The ECSA-HC is a regional intergovernmental health organization that fosters and promotes regional cooperation among fourteen member states. SPRING played a lead role in strengthening enforcement and regulation with partners and the ECSA Health Secretariat, which accelerated the region’s efforts in food fortification, harmonization of standards, and cross-regional learning.

As the interim chair of the inspection and enforcement working group, SPRING, along with UNBS, offered technical guidance and coordination to harmonize ECSA inspection guidelines and manuals. This coordination required that the internal and external manuals for industries and food vehicles (sugar, oil, and salt) be merged into one unified manual and that manuals for commercial and import inspections be combined. SPRING supported the coordination of activities for the ECSA Regional Laboratory Working Group, a group of laboratory specialists representing regulatory, academic, and research laboratories active in analysing fortified foods and other micronutrient issues.

SPRING has since designated UNBS as the government body responsible for the chairmanship role in coordinating activities of the working group to ensure sustainability beyond SPRING.

SPRING also conducted a desk review of existing food fortification communications materials (print materials and radio spots) and facilitated a stakeholders meetings in partnership with the Communication for Development Foundation Uganda (CDFU) to review and update existing materials with consistent messages. CDFU finalized the TV script (English), camera-ready print materials, and an English radio spot that was translated in Luganda, Lusoga, Luo, and Runyankole.

We shared these materials with the MOH, which is now responsible for maintaining and disseminating IEC materials on fortification. The government will need to incorporate mass media campaigns into their budget. Sector ministries, civil society, and other partners need to mobilize resources to support advocacy and promotion activities.

Enforcement of Policies and Standards

Successful fortification programs must be equipped to enforce national standards and monitor the quality of fortified foods. Industries must also understand the national standards and be clear about how the government will measure the quality of food samples. SPRING assisted the government with training regulators and enforcers in the public sector as well as industry representatives in understanding the national standards. SPRING revised a training manual and training curriculum for producers and regulators of fortified foods to incorporate changes in the standards for fortified foods. UNBS disseminated 200 copies of the training manual and curricula to the industries and regulators. Topics of the training programs included:

- The Basics of Food Safety: Good Manufacturing Practices (GMP): Industry personnel responsible for the quantity, quality, and safety of fortified foods received in-house training on GMP/good hygiene practices (GHP). In 2014, 139 participants from 14 industries (8 wheat flour producers, 4 oil and fat producers, and 2 maize flour producers) were trained on the basics of food hygiene and food safety.

- Harmonized East Africa Community Standards: SPRING and the government taught 212 participants from 14 companies (wheat flour producers, oil and fats producers, and maize flour producers) the requirements of the harmonized East Africa Community (EAC) standards of fortified foods for manufacturers through theory-based and practical sessions. Participants learned to implement standards at the factory and industry levels.

- Training on Hazard Analysis and Critical Control Points (HACCP): HACCP is a systematic preventive approach to food safety from biological, chemical, and physical hazards in production processes that can cause the finished product to be unsafe. We trained 42 technical officers from 21 industries engaged in food fortification about the assessment and analysis of hazards as well as food safety management and control.

- Monitoring and Regulation of Fortified Foods: We trained 66 district health inspectors (DHI) and 33 National Drug Authority (NDA) inspectors on the monitoring and regulation of fortified foods, focusing on the enforcement of EAC food standards.

- Storage Facility Inspections: SPRING supported the NDA to conduct storage facility inspections for fortificants and premixes. The NDA has now dedicated staff for this activity.

SPRING also provided a guide on the interpretation of national standards to industry representatives and to the enforcement officials. SPRING supported the review of existing quality assurance/quality control (QA/QC) manuals, identified the gaps, and then updated the manuals per the latest national and regional regulatory requirements. We printed and disseminated 400 manuals to industries and other stakeholders on regulatory monitoring of fortified foods including QA/QC manuals for wheat flour producers, oils and fats producers, and maize flour producers.

SPRING’s training programs have increased the capacity of industry personnel, regulators, and inspectors. But with high staff turnover in the industry, new trainings and refresher trainings must be held every six months. Ideally, industries would pay for the trainings, however many industries would not invest in the training as this is seen to increase operational costs. If the GOU lacks the resources to provide new trainings and refresher trainings, they will need to mobilize an outside organization to support training efforts. Sector ministries should also prioritise training as one of the key activities in their annual plans.

SPRING has trained regulators to monitor the quality of fortified foods, but at the country’s entry points, there are not enough inspectors to conduct surveillance of imported fortified foods. As a result, some unfortified products are entering the country and are being sold in the local market at a cheaper price than fortified Ugandan products. Targeted testing of retail products could help to weed out the unfortified foods.

Organizing trainings does not ensure that facilities will adopt the practices. Trainings must be accompanied by compliance checks, including inspection, sampling, and analysis. UNBS must incorporate this cost into its budget.

Program Monitoring

Food fortification programs conduct monitoring at three levels: production, retail, and consumption. Monitoring ensures that fortified food has the correct level of micronutrients, taking into account the many ways a person may consume micronutrients in their diet. Food fortification standards were voluntary in Uganda when they were introduced in 2004. However, after seeing the success of the fortification program, the government made fortification mandatory for oil and wheat flour producers.

Industry Level Monitoring: SPRING supported the UNBS to inspect industries, collect samples of fortified foods, and verify the company’s QA/QC system compliance with applicable Uganda standards and good manufacturing/ hygiene practices (GMP/GHP). The results determined whether the company was following the mandatory food fortification regulations.

Inspections targeted manufacturers of fortified wheat flour, milled maize products, and vegetable cooking oil and fats. The inspection covered the process from raw material reception to final product packaging and included staff hygiene, facilities, stores, laboratories, and production areas. The results showed that:

- There has been progressive improvement in compliance with mandatory fortification standards. However, some wheat flour samples failed to meet required vitamin A levels.

- From 2013 to 2016, the oil samples collected from the different industries increased from 40 to 60 percent compliance with fortification standards.

SPRING expanded the capacity of the monitoring system for quality food fortification in the country by supporting the certification and recognition of five laboratories as having adequate testing capacity for fortified foods (BIDCO, Mukwano Industries, Reco Industries, Uganda Industrial Research Institute [UIRI]and Chemipher Laboratories). Laboratory recognition by UNBS means the facility can test fortified food samples.

Previously, UNBS was the only facility equipped to assess whether an industry was adhering to the appropriate fortification standards. The five additional laboratories will relieve UNBS’s testing backlog.

MTIC is currently establishing a large new laboratory complex at the UNBS headquarters, which will boost laboratory capacity and require trained laboratory staff. Additional inspectors should be trained, and laboratories should undergo proficiency testing.

Retail Level Monitoring: SPRING supported UNBS to conduct the first-ever nationwide market survey to assess the coverage and quality of fortified foods across districts at the retail level. Inspectors assessed fortified foods distributed at the district level for quality, looking at whether the foods contained adequate levels of micronutrients and whether they met the minimum labeling requirements. Inspectors also looked for adulterated products and counterfeits. Findings indicated that fortified foods were available in all the districts sampled, and inspectors did not observe any counterfeits or visible adulteration of fortified foods. There are currently no plans to conduct another market survey, given the cost and resources required.

Consumption Level Monitoring: This monitoring was done at the household level as part of the impact assessment.

SPRING's Validation of Fortification Testing Methods

In 2016, SPRING conducted research to validate the use of iCheck rapid test kits as a means of analysis for fortified food samples and to compare the cost of using iCheck kits versus using traditional methods. Findings from the study suggest that iCheck should be rigorously evaluated in more than one country. There are still pending issues about accuracy and blank readings that must be solved before considering the continued use of this equipment to determine vitamin A and iron levels in flours. We also examined two types of iron mixtures for flour fortification and found that Uganda should consider using ferrous fumarate as the only iron for wheat flour fortification.

SPRING supported a follow-up study on the validation of five testing methods for iodine in salt. The methods include titration, WYD, iReader, iCheck iodine and UV/Visible Spectrophotometry. Titration proved to be the most accurate and precise overall, but at concentrations above 10 parts per million, spectrophotometry has the potential to replace titration because of its lower cost, reliability, and simplicity to implement.

Impact Evaluation

The success of fortification programs can be measured through decreases in micronutrient deficiency in the population, and this data on micronutrient intake is most accurately collected through individual consumption surveys. SPRING assisted the MOH and the Uganda Bureau of Statistics (UBOS) to integrate food fortification indicators into the Uganda Annual National Household Survey. The government is now equipped to collect data related to regulatory monitoring and household indicators. These tools should provide programme planners and policymakers with the necessary information to make evidence-based decisions. The government plans to conduct the next Annual Household Survey in 2018 and will collect data on food fortification indicators.

In June 2017, at the third ECSA regional meeting in Maputo, GAIN and Project Healthy Children showed interest in supporting governments in the ECSA region to develop a regional monitoring and evaluation system. However, individuals countries must agree to harmonize their own monitoring and evaluation methods and this will require government commitment. The government of Uganda expressed interest in this effort, and as a result, the Global Alliance for Improved Nutrition visited with the government in October 2017 to plan the way forward.

Conclusion

SPRING/Uganda has supported the government of Uganda to make great strides in the area of food fortification, both at the national and regional levels. Because of the revival of the NWGFF, which spearheaded the development of a five-year multi-sectoral national industrial food fortification strategy to building the capacity of producers and regulators of fortified foods to ensure the availability of quality fortified products which adhere to regional ECSA standards, Uganda is well on its way to becoming a leader in national fortification programs. For sustainability of the food fortification initiative, the five-year multi-sectoral strategy provides a roadmap for institutionalizing food fortification activities into ongoing sectoral work plans and budgets.

With a dedicated MOH staff member to coordinate the NWGFF’s activities, the working group can continue its mission of steering the national fortification program. We recommend the NWGFF lead biannual meetings with the sectors, development partners, and industry representatives to achieve this goal.

As described in the national industrial food fortification strategy, the NWGFF can facilitate the removal and/or reduction of barriers to food fortification for industries of all sizes. The group can tackle tax incentives on fortification equipment and other supplies, and create avenues for the bulk purchase of pre-mix and fortificants. The working group can also support the scale-up of fortification to include additional vehicles, such as sugar, milk, cassava, rice, and complementary foods. The national food fortification strategy includes activities and estimated costs for this scale-up, but public and private partners’ support will be necessary to implementation fortification.

Now that small-scale millers are interested in fortifying their products and have boarding schools as potential customers, they need support to purchase and maintain fortification equipment. SPRING prepared resources outlining technology options for small-scale fortification. The next step will be to identify an implementing partner who can support the procurement of the equipment.

Regulation and enforcement of fortified foods will need to be sustained and scaled up to match the growing supply of fortified products. The Government of Uganda and development partners will need to continue to organize trainings for industry personnel, regulators, and inspectors, using training manuals and curricula updated by SPRING. New laboratories should be certified to test fortified food products. SPRING supported the certification and recognition of five additional laboratories, a certification program that should continue to serve as a source of revenue for UNBS and to increase the testing capacity for fortified foods.